How to Make a Lean-To Shed DIY: A Budget-Friendly Outdoor Project

Constructing a lean-to shed offers a practical and cost-effective solution for expanding outdoor storage or creating a sheltered workspace. This detailed guide provides a comprehensive overview of the process, emphasizing budget-friendly techniques and materials selection while maintaining structural integrity and durability.

Phase 1: Planning and Preparation

Before commencing construction, meticulous planning is crucial to ensure a successful outcome. This involves several key steps:

Site Selection and Assessment

Choosing the appropriate location is paramount. Consider factors such as:

- Accessibility: Ensure easy access for materials delivery and future use.

- Ground Conditions: Evaluate the terrain for stability and drainage. Level ground is ideal, minimizing excavation and foundation complexities.

- Sunlight and Shade: Determine the desired level of sunlight exposure for the shed’s intended purpose. Consider the impact of sun and shade on temperature regulation.

- Proximity to Utilities: Maintain sufficient distance from power lines, gas meters, and other utilities to prevent accidental damage or interference.

Design and Dimensions

The dimensions of your lean-to will depend on your storage needs and available space. Sketch a detailed plan, noting the length, width, and height of the structure. Consider the following aspects:

- Roof Slope: A steeper slope facilitates better water runoff, especially in areas with high rainfall.

- Wall Height: Determine the desired height of the side walls for comfortable access and storage.

- Door Placement: Strategically plan the placement of the door for ease of access and efficient space utilization.

Materials Procurement

Selecting cost-effective yet durable materials is essential for a budget-friendly project. Consider the following:

- Pressure-Treated Lumber: Opt for pressure-treated lumber for the foundation and framing to enhance resistance against rot and insect infestation. This is a worthwhile investment despite the higher initial cost.

- Plywood or OSB Sheathing: Plywood or oriented strand board (OSB) provides a cost-effective solution for wall and roof sheathing. Ensure you select the appropriate grade for exterior use.

- Roofing Material: Choose a roofing material that suits your budget and climate. Options include asphalt shingles, corrugated metal sheets, or recycled plastic roofing.

- Fasteners: Use galvanized or stainless steel nails and screws to ensure longevity and resistance to rust.

Phase 2: Construction

With planning complete, the construction phase begins. This involves several key steps:

Foundation Preparation

A stable foundation is crucial for the longevity of your lean-to shed. For a budget-friendly approach, consider these options:

- Gravel Base: A simple and cost-effective option is to create a gravel base, ensuring proper drainage. Level the ground, and lay down a layer of gravel several inches deep. Compress the gravel thoroughly to provide a stable foundation.

- Concrete Piers: For increased stability, especially in soft soil, pour small concrete piers at strategic locations along the shed's base.

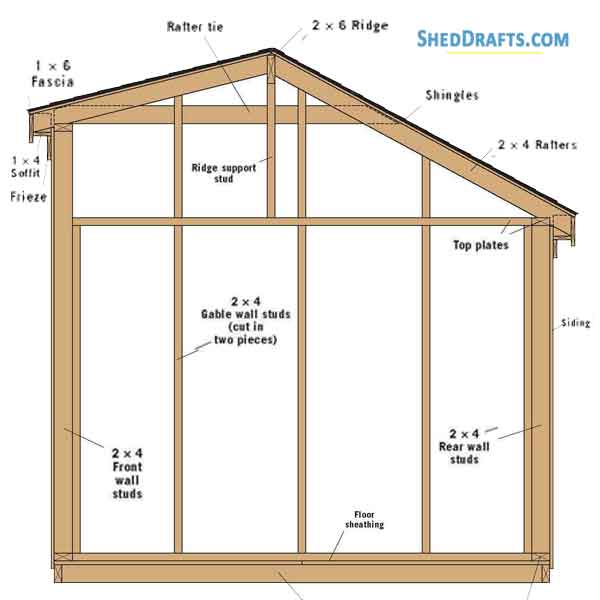

Framing the Structure

The framing forms the skeletal structure of your lean-to. Begin by building the foundation wall framework. This typically involves creating a frame using pressure-treated lumber. Ensure that the frame is square and level using a level and measuring tape. Once the foundation is complete, erect the supporting posts for the roof. These posts should be firmly anchored into the ground or the foundation. The roof rafters should then be carefully attached to the supporting posts and the foundation wall.

Sheathing the Walls and Roof

Once the frame is erected, attach the plywood or OSB sheathing to the walls and roof. Ensure proper alignment and secure fastening to prevent movement. This step provides a solid surface for the exterior cladding.

Roofing Installation

The roofing is a crucial element protecting your shed from the elements. Begin by installing underlayment to provide an additional barrier against moisture. Then, install your chosen roofing material according to the manufacturer's instructions. Ensure proper overlapping and sealing to prevent leaks. Pay close attention to flashing around any penetrations, such as vents or chimneys, if applicable.

Door and Window Installation (Optional)

If you’re including a door and/or windows, this is the time to install them. Ensure that the openings are properly framed and sealed to prevent drafts and moisture intrusion.

Phase 3: Finishing Touches

The final steps enhance the appearance and functionality of your lean-to shed.

Exterior Finishing

Consider applying a weather-resistant sealant or paint to protect the wood from the elements and enhance the aesthetic appeal. Choose a paint formulated for exterior use and follow the manufacturer's instructions carefully.

Interior Finishing (Optional)

If you intend to use the shed for more than simple storage, consider adding interior finishes. This could involve painting the interior walls, adding shelving, or installing a work bench.

Safety Considerations

Throughout the construction process, prioritize safety. Wear appropriate personal protective equipment (PPE), including safety glasses, work gloves, and sturdy footwear. Ensure that all tools and equipment are used correctly and safely. If working at heights, use proper fall protection. Always adhere to local building codes and regulations.

By following these steps and employing budget-conscious strategies, you can successfully construct a durable and functional lean-to shed that meets your needs while staying within your budget. Remember to always prioritize safety and carefully review all instructions before beginning the project. A well-planned and executed project will provide years of useful outdoor storage or workspace.